The long road

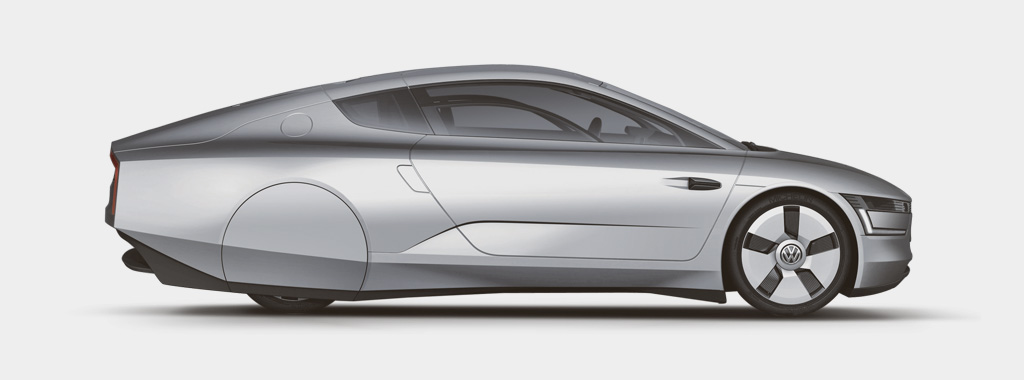

VOLKSWAGEN XL1

There’s no single route towards sustainable mobility. That’s why Volkswagen Group researchers and developers are working simultaneously on a range of new technologies. The aim, as always, is to create more motoring enjoyment using less energy.

When the Golf 1 first appeared in 1974, customers had a choice between two types of petrol engine. A three-gear automatic gearbox was available on request for the more powerful 70 PS engine (51 kW). Today’s Golf customer has many more options to choose from. Engine output ranges from 63 kW to 221 kW (85 – 300 PS) for petrol engines and from 81 kW to 135 kW (110 – 184 PS) for diesel ones. In addition, there is a particularly economical gas-powered variant with an output of 81 kW (110 PS). A direct-shift gearbox takes care of gear changing. It handles this without any loss of traction, so smoothly and quickly that usually the driver can only detect the change by checking the tachometer. A plug-in hybrid and an electric variant have joined the family in 2014, just in time to celebrate the Golf’s 40th birthday.

This car – which embodies the Volkswagen brand more than any other – reflects the variety of drive types that will be available in the future. The key to this is the Modular Transverse Toolkit (MQB) – a uniform vehicle architecture used for many models across the Group’s different brands, in which the engine is mounted in a transverse arrangement.

TDI engine

A model of efficiency: state-of-the-art diesel engines such as the Audi 4.2-liter V8-TDI combine smooth running, exceptional torque and low fuel consumption.

Looking across the whole Volkswagen Group, the diversity of drive types is even greater, ranging from the small two-cylinder engines developed by Ducati for its motor cycles right up to Scania’s V8 truck engines, where a single cylinder has a capacity of more than two liters. The drive types are as diverse as the vehicle concepts. And yet, when you listen to engine developers talking, they all share the same top priority – efficiency: how can the energy stored in the fuel best be used to create forward movement?

The automobile industry is investing a great deal of knowledge and money in a bid to answer this question – because for the foreseeable future the combustion engine will remain the most important drive type. According to consultants McKinsey, 90 percent of all new cars will still be powered exclusively by combustion engines even in 2020. The proportion of commercial vehicles will be even higher. Petrol engines, mostly with three or four cylinders, are the first choice for many people across the world when they buy a car. So in addition to the new Golf, Volkswagen has launched a new Modular Petrol Engine System which will be used in many Group models in the future. Higher production numbers mean that costly fuel-saving technologies, such as direct-injection petrol engines or exhaust-driven turbo charging, can be produced even more economically. The particularly environmentally friendly gas-powered TGI models are also based on petrol engines. In comparable driving conditions, they emit 25 percent less carbon dioxide because gas contains less carbon for the same energy content.

“Our top priority is to make combustion engines even more economical.”

Ulrich Weiß develops diesel engines at Audi’s facility in Neckarsulm.

From the very beginning, the diesel engine has been regarded as the most efficient engine of all. “This will continue to be the case in the future”, explains Ulrich Weiß. Having trained as a mechanical engineer, he develops six- and eight-cylinder TDI engines at the Audi plant in Neckarsulm for premium vehicles such as the Audi A82. Customers who buy these cars expect the ultimate in smooth driving and exceptional torque, but at the same time the lowest possible fuel consumption and minimal emissions. That’s a real challenge for developers, because as Weiß points out, “in terms of the physics, these aims are incompatible.”

Weiß and his team have achieved the seemingly impossible. Right from the early stages of developing new engines, they look at the most effective ways to clean up emissions. Audi engines, for example, inject miniscule droplets (one cubic millimeter) of diesel fuel at up to 2,500 times air pressure into the cylinder. This results in finer fuel atomization and cleaner combustion. The remaining exhaust particles, which are subject to legal limits, are removed by the exhaust cleaning system. What is special about the Audi system is the combination of two catalytic converters and a particle filter in a single compact unit which can be installed near the engine, where the high temperatures mean it can work extremely effectively.

Diesel is the top choice for long-distance drivers – particularly in Europe, where nearly every second new car has a diesel engine. But in China and the United States, the biggest auto markets in the world, the number of diesel cars sold is much lower. Weiß intends to change that. “We are already seeing a noticeable increase in customer acceptance in the USA.” And in China, too, the first Volkswagen and Audi diesel models are already out on the road.

“With electric and hybrid drives, we have entered new technological territory. Exciting times for us engineers!”

Hanno Jelden develops electric drives for Volkswagen.

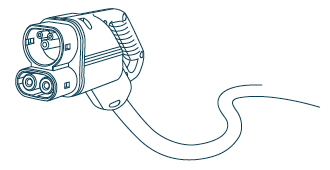

The dual plug

The Combined Charging System can be connected both to AC chargers at home or at work and to DC fast charging stations.

In Asia and also in the USA, hybrid drives in which the regular petrol engine is enhanced by an electric motor play an important role. It’s a fascinating principle, one which Volkswagen researchers had already been working on for many years when Hanno Jelden took over responsibility for all electric drive components. His task was to develop vehicles with hybrid and electric drives ready for series production. The first was the Volkswagen Touareg Hybrid3, followed by Audi and Porsche vehicles. “In the course of this project, we learned how to optimize the interaction between the two engines and the transmission. Today’s driver doesn’t even notice the gears changing or the shifts between the combustion engine and the electric motor”, is how Jelden sums the work up.

Depending on their design, hybrid vehicles use between 15 and 25 percent less fuel. “That wasn’t enough for us”, says Jelden. Parallel to the development of series models, he tested a variety of alternative solutions. Plug-in hybrids, whose batteries can also be charged through normal electric sockets, are of particular interest. If the battery is large enough, the electric motor can be designed to deliver strong performance and the plug-in hybrid can travel up to 50 kilometers on electricity alone. According to a study by the Fraunhofer Institute, the average German driver travels only 42 kilometers a day. This means that a plug-in hybrid frequently runs on electricity alone during everyday use, but can also travel longer distances at any time, thanks to its combustion engine. “This kind of car also delivers very dynamic driving”, explains Jelden. “Because when you need it, say when you’re overtaking, you can access the power of both engines.” The combination of efficiency and dynamic driving offered by a plug-in hybrid will be a feature of many Volkswagen Group models in the future. The Porsche Panamera S E-Hybrid4 was the first, in summer 2013, and the technology will also be available for the Golf approximately one year later.

Because their range is still limited, pure-play electric cars running on lithium-ion batteries will be found primarily in cities in the foreseeable future. It’s no surprise, then, that Volkswagen’s first electric car is the e-up!5 city runabout. Consuming only 11.7 kWh per 100 kilometers, it is the most efficient electric vehicle in the world. That’s not an end in itself, explains Jelden. “The e-up!’s low energy consumption means it can travel for around 160 kilometers before the battery needs recharging.” To keep energy requirements as low as possible, Volkswagen’s engineers examined every last detail – from the tires right through to the engine cooling system – looking for unnecessary power-eating elements and finding effective solutions. This enabled them to design a lightweight battery for the e-up! at an attractive price.

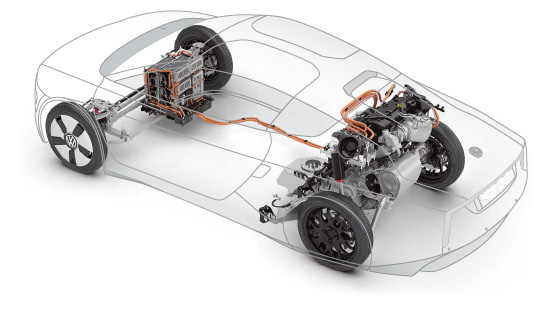

When you travel light, you travel further – this also holds true for the Volkswagen XL16, the world’s first one-liter car. Holger Bock, who has been in charge of the project for many years, calls it “a road test for new technologies”. Take the monocoque made of carbon fibers (CFK), for example – a body-in-white which is manufactured in one piece and weighs only 90 kilograms. Comparable bodywork made of steel would weigh more than twice as much. “We save a lot of time compared with the previous assembly process because we no longer need to stick the individual parts together”, explains Bock. The specially designed large-scale machine tool on which the bodywork is formed by “baking” together individual carbon fiber mats over a period of two hours, is a world first. “We will be able to use the knowledge we have gained in other series in the future.” The same applies true for the drop-shaped aerodynamic design of the XL1, the external mirrors which have been replaced by cameras (e-mirrors), and the combined diesel-hybrid drive (see image on bottom of the page for technical details).

What do engineers Bock, Jelden and Weiß have in common? They keep pushing forward into new territory – and they are three of the more than 40,000 people developing new vehicles and technologies in the Volkswagen Group. However, future-proof mobility concepts require more than just the creativity of electrical and mechanical engineers. An electric car is only climate-neutral when it uses renewable energy, for example. Volkswagen Financial Services can arrange a suitable contract for this if required. And every customer who opts for an e-up! and at some time decides to drive off on vacation can hire a more spacious combustion-engine car for up to 30 days a year, free of charge, from Euromobil, the car-hire business owned by Volkswagen Financial Services.

The road to mobility in the future is long, with many forks. Despite all the market research, it is still impossible to predict how soon alternative drive concepts will achieve a breakthrough with customers. The most important thing is to be ready for the change. In every respect. And that’s why the new Golf, which for the first time is based on the Modular Transverse Toolkit (MQB), can be delivered with any drive type requested by the customer. Petrol, diesel, gas-powered and electric drive models are all produced on the same assembly line. This makes economic sense, both for Volkswagen and for customers – because fuel-saving drivetrains only help to protect the environment if they are out on the roads.

“Efficiency isn’t just about the drive technology – it also means working on every detail of the vehicle.”

Holger Bock was project manager for the XL1 and is responsible for the up! and the Polo, among other things, in his role as general vehicle project manager.

Nadja Lucchini-Kranz,

Head of International Marketing and Innovations,

Volkswagen Financial Services AG

“Innovative services are becoming more and more important.”

How Volkswagen Financial Services supports new mobility concepts.

Why is Volkswagen Financial Services getting involved with new mobility concepts?

Our brief is clear: to support sales by the Volkswagen Group brands and to increase customer loyalty. For example, when brands bring out vehicles with alternative drives, it’s our job to help them succeed in the market by offering new types of products and services.

What role does e-mobility play in that?

E-mobility is a good example for how the portfolio of an automotive financial services provider is developing and changing. Take our Blue Power contracts for green electricity, for instance. We can offer these to customers buying electric vehicles who want to run them on renewable energy.

What role will car sharing play in the future?

Many car sharing schemes are still operating at a loss. One exception is Greenwheels in the Netherlands, which has approximately 2,000 vehicles. That’s why Volkswagen Financial Services invested in the company in 2013. This gives us the opportunity to find out more about sustainable customer requirements, just as we do in our own car sharing pilot project, Quicar, in Hanover.

Can concepts like these be translated into overseas markets?

There is a very strong desire, particularly in Asia, to make sure that the mobility boom is sustainable right from the start. This is why we established Volkswagen New Mobility Services in China. That will help us take advantage of the opportunities we see along the automobile value chain, particularly in the megacities.

XL1

Electric motor

(20 kW / 27 PS)

140 Nm

Up to 50 km range purely on electricity, with zero emissions

XL1

Two-cylinder

TDI engine (35 kW / 48 PS)

7- speed direct shift gearbox (DSG)

795kg – what the most economical series car in the world weighs.

VOLKSWAGEN XL1

Volkswagen is pushing the boundaries of what is technically achievable: efficient diesel hybrid drive, minimal weight, aerodynamic perfection – making 0.9 liters average fuel consumption a reality.

HIGH-VOLTAGE BATTERY

Lithium-ion battery with 5.5 kWh capacity.

LIGHTWEIGHT BODY CONSTRUCTION

Thanks to the carbon-fiber monocoque, which includes wing doors and a laminated glass windscreen, the body weighs only 230 kilograms.

LOW-ROLLING RESISTANCE TIRES

The tires work in conjunction with the extremely aerodynamic bodywork (Cd of 0.189) to achieve even greater energy efficiency.

MAGNESIUM FORGED WHEELS

High-tech lightweight construction: so light that they can be lifted with only one hand.

TWO-CYLINDER TDI

The efficient lightweight diesel engine working in conjunction with the electric motor emits a mere 21 g/km of CO2.

CERAMIC BRAKES

Gripping: the XL1’s braking system features include fast response, rapid cooling, minimal weight and resistance to corrosion.

TITANIUM EXHAUST SYSTEM

Titanium – the material of the future: very light and strong, withstands temperature differences and corrosion.

ELECTRIC MOTOR

The XL1 uses less than 0.1 kWh per kilometer when in electric mode.

DSG LIGHTWEIGHT TRANSMISSION

7-speed direct shift gearbox, developed by Volkswagen.

1 Volkswagen Golf fuel consumption in l/100 km combined from 5.2 to 3.2; CO2 emissions in g/km combined from 122 to 85.

2 Audi A8 fuel consumption in l/100 km combined from 9.1 to 5.9; CO2 emissions in g/km combined from 213 to 144.

3 Volkswagen Touareg Hybrid 245 kW fuel consumption in l/100 km urban 8.7 / extra-urban 7.9 / combined 8.2; CO2 emissions in g/km combined 193.

4 Porsche Panamera S E-Hybrid 306 kW fuel consumption in l/100 km combined 3.1; energy consumption in kWh/100 km combined 16.2; CO2 emissions in g/km combined 71.

5 Volkswagen e-up! 60 kW energy consumption in kWh/100 km combined 11.7; CO2 emissions in g/km combined 0.

6 Volkswagen XL1 fuel consumption in l/100 km combined 0.9; energy consumption in kWh/100 km combined 7.2; CO2 emissions in g/km combined 21.

Audi A3 Sportback fuel consumption in l/100 km combined from 6.5 to 3.3; CO2 emissions in g/km combined from 149 to 88 (see figure).

Volkswagen e-Golf 85 kW energy consumption in kWh/100 km combined 12.7; CO2 emissions in g/km combined 0 (see figure).